Force Measuring Systems AG (FMS), headquarted in Switzerland with operations in the United States, is a global leader in precision tension measurement and control solutions for coating & extrusion applications. This post focuses on tension sensors (also called load cells, transducers, force sensors, or strain gauges). Here are the key advantages that specifically sets FMS apart from other solutions on the market:

1. Exceptional Accuracy and Reliability

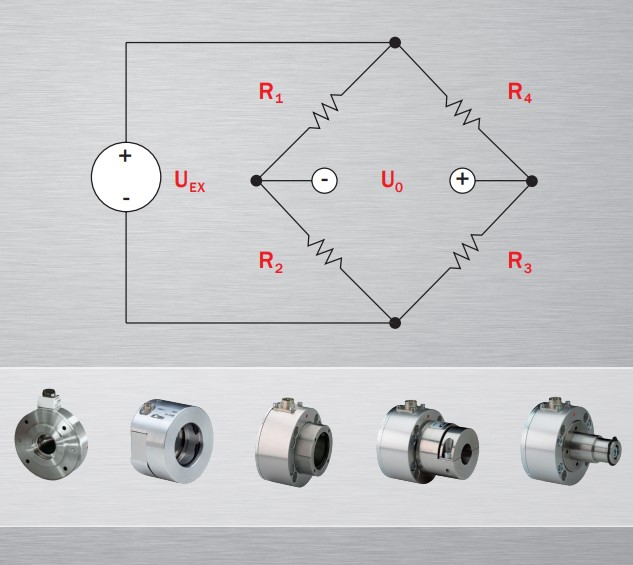

FMS sensors are designed with advanced strain gauge technology in a full Wheatstone bridge configuration, ensuring precise tension measurements even under challenging conditions. This setup provides high accuracy, operational reliability, and stability, making FMS equipment ideal for maintaining consistent material tension across various applications. Competitive semiconductor technologies only use half of the Wheatstone bridge. Sensors utilizing only half of the bridge are sensitive to ambient temperature changes, and are more susceptible to electromagnetic noise. With no passive resistors, full bridges avoid errors from resistor tolerance mismatches. Additionally, the output voltage from a full bridge becomes four times the signal of a single gauge. This dramatically improves the ability to detect minute resistance changes caused by strain, enabling higher measurement resolution.

2. Built-In Overload Protection

A standout feature of FMS tension sensors is their mechanical overload protection, which prevents damage during extreme conditions. This design reduces the need for frequent calibration and enhances durability, making the sensors virtually indestructible. In fact, FMS sensors will not lose calibration over time due to their highly robust construction. Competing sensors are designed with only a slight margin above their maximum strain capacity, making them susceptible to damage if the tension surpasses the rated threshold.

3. Application Flexibility

FMS offers a wide range of force sensors tailored to specific needs, capable of measuring tensions from less than 1N to over 100kN. They are available in diverse mounting configurations (e.g., flange mount, pillow block) and versions for live or dead shafts, ensuring compatibility with various materials like paper, film, foil, plastics, rubber, wire, and cable.

4. Advanced Electronics for Seamless Integration

FMS electronic units include tension measuring amplifiers. These amplifiers communicate with closed-loop controllers that process sensor signals with precision. These units support both analog and digital outputs (e.g., 0–10V, 4–20mA) and integrate seamlessly with modern systems via interfaces like PROFIBUS, RS232, and DeviceNet, enabling efficient control and monitoring.

5. Enhanced Productivity and Cost Efficiency

Using FMS tension sensors leads to minimized waste, reduced machine downtime, and improved amortization periods. The exceptional durability and overload protection ensure that there is minimal failure in the field. These benefits directly contribute to higher operational efficiency and lower overall costs.

6. Simplified Installation and Operation

FMS products prioritize user-friendly designs with easy installation processes. Their electronic units feature built-in signal filtering and vibration resistance for smooth operation in demanding environments.

By combining cutting-edge technology with robust designs and application-specific solutions, FMS tension sensors deliver unmatched performance in web processing applications. Their ability to enhance productivity while maintaining reliability makes them the preferred choice for manufacturers worldwide.

7. Excellent Technical Support and Post-Sales Experience

As a privately held company, FMS operates with the flexibility and agility needed to quickly respond to customer inquiries and evolving industry demands. Without the bureaucratic constraints of larger corporations, FMS can prioritize customer needs, delivering timely solutions and personalized support. This responsiveness ensures that clients receive the best possible service, whether they require a custom tension measurement system or technical guidance.

Additionally, FMS offers a powerful online tool, the FMS Force Sensor Calculator, to assist engineers in properly sizing their required sensor. This user-friendly resource simplifies the selection process, ensuring accuracy and efficiency in choosing the optimal tension sensor for specific applications.

Take the Next Step

FMS web tension sensors are a great addition to any process where tension monitoring is critical. FMS also offers other technologies, such as segmented web tension rollers for tension profiling. These are an excellent upgrade if you want to learn where tension variations are occurring along your web width.

Are you ready to optimize your tension measurement and improve your production efficiency? Contact us today and let’s discuss your project!

Founder, Gauge Advisor LLC