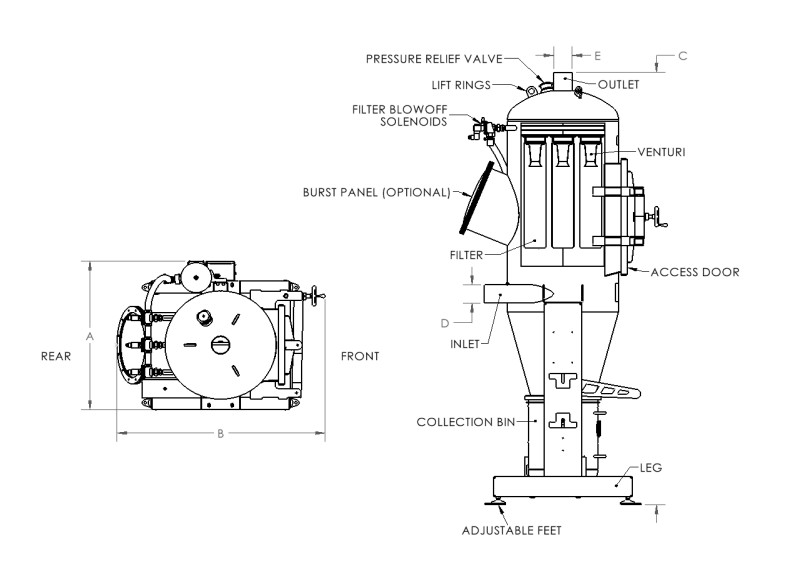

When selecting air filtration and dust collection systems for your facility, performance, reliability, and safety are key engineering requirements. Advanced Blending Solutions (ABS) Air Filtration Units are built to exceed those expectations with intelligent design and operator-centric features to improve efficiency. The unit is engineered for use in conveying bulk materials with particle sizes as small as 10 microns. It can operate at vacuum levels up to 16 inches of Mercury.

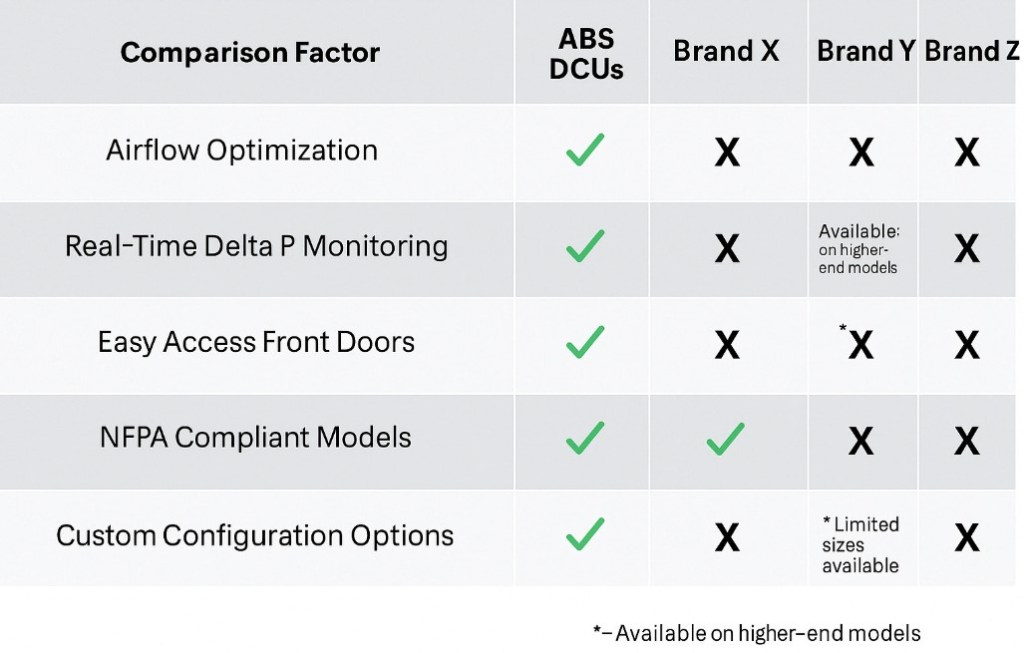

Whether you’re designing a new system or upgrading an existing one, here’s why engineers consistently choose ABS.

1. Optimized Airflow = Maximized System Performance

Engineers know that pressure drop is the silent killer of system efficiency. ABS air filtration units are designed to minimize airflow restrictions, ensuring that blowers operate within their optimal performance curves. This reduces energy consumption, protects downstream equipment, and helps maintain consistent air quality.

Key Design Features:

- Streamlined flow paths to reduce turbulence and pressure loss

- Filter configurations designed to minimize clogging and extend service life

- Precise sizing options to match system airflow requirements

2. Delta P Monitoring for Data-Driven Maintenance

Forget arbitrary filter changes or inefficient timed cleanings! ABS air filtration units use precise delta P (∆p) measurements to monitor pressure drop across the filters in real time.

Why It Matters to Engineers:

- Enables on-demand cleaning cycles, reducing compressed air usage

- Extends filter life and reduces maintenance intervals

- Supports predictive maintenance strategies and minimizes unplanned downtime

3. Designed for Easy Access and Fast Servicing

Maintenance accessibility is often overlooked until it becomes a problem. ABS air filtration units solve this with thoughtful mechanical design.

Ease-of-Use Features:

- Front-access doors for quick inspections and filter replacements

- Quick-release clamps for tool-free filter changes

- Auto blow off for automated filter cleaning based on pressure monitoring

- Removable collection bins for clean and efficient waste removal

- Collection bin automation (optional) for knife-gate activated waste discharge into a customer’s gaylord bin – no labor required

These features directly translate to reduced labor costs and faster turnaround during servicing.

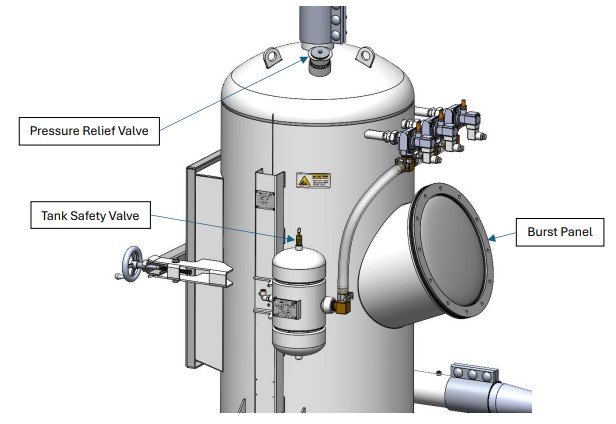

4. Safety for Combustible Dust & Robust Design

If your process involves combustible dust, safety compliance is non-negotiable. ABS offers NFPA-compliant systems rated up to ST2 Hazard-Class materials, ensuring peace of mind and regulatory alignment when working with combustible dust.

Engineered Safety Features:

- Pressure relief valves to handle excess pressure

- Burst panel to protect against explosions

- CE-compliance for international applications

- Heavy gauge sheet metal for extreme vacuum conditions associated with dilute phase conveying.

5. Custom Configurations for Engineered Systems

ABS understands that no two processes are the same. That’s why ABS air filtration units are offered in multiple sizes, filter types, and inlet/outlet options, to work with pumps rated from 5 to 100 HP.

Customizable Parameters:

- Diameter sizes: 16″, 24″, and 32″

- Filter options: 16oz Polyester Felt Bags or PTFE-membraned Pleated Filters

- Inlet/outlet sizes and breaker valve availability

These flexible configurations allow engineers to integrate ABS units into both standard and specialized applications without compromise.

Conclusion: A Practical Solution to Complex Air Filtration

Selecting the right dust collection system involves more than just meeting minimum requirements. It’s about designing for long-term efficiency, maintainability, and compliance. ABS air filtration units offer a solution grounded in engineering fundamentals: optimized airflow, intelligent filter monitoring, accessible serviceability, and safety features aligned with NFPA standards.

For engineers seeking to balance performance, regulatory compliance, and system longevity, ABS DCUs present a well-rounded, configurable platform adaptable to a wide range of industrial applications.

As always, final selection should consider specific process variables, dust characteristics, and facility layout. However, for many engineered systems, ABS provides a reliable and proven starting point.

Why Partner with Advanced Blending Solutions:

📅 1-Year Equipment Warranty

⭐ Customers Love ABS on Google

✅ U.S.-Based Design, Service & Manufacturing

👉 Contact us today today to schedule a demo or request a quote.

Let’s size an appropriate air filtration unit to improve your plant’s operational efficiency.

Founder, Gauge Advisor LLC