Anyone running rigid PVC pipe extrusion knows it’s not the easiest material to process. PVC is shear-sensitive, temperature-sensitive, and unforgiving when it comes to pressure fluctuations. Push it too hard, and you’ll see scorching, gels, or wall-thickness variations. Run it too soft, and throughput suffers, die pressure becomes unstable, and your extruder wears out faster than it should.

Most of the time, the extruder is asked to do it all: plasticizing the resin and building the pressure needed to push material through the die. That’s where things get tricky. The extra work drives up melt temperature, increases energy consumption, and makes it harder to keep output consistent.

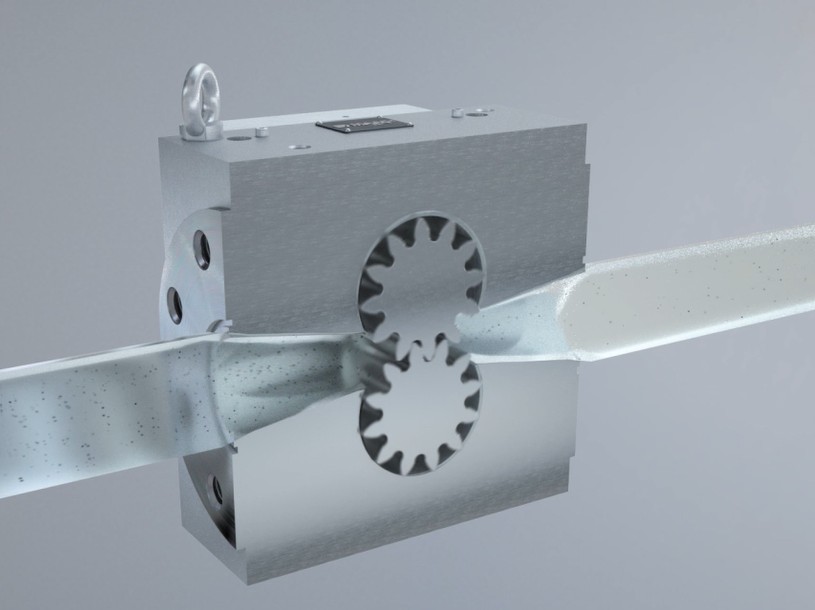

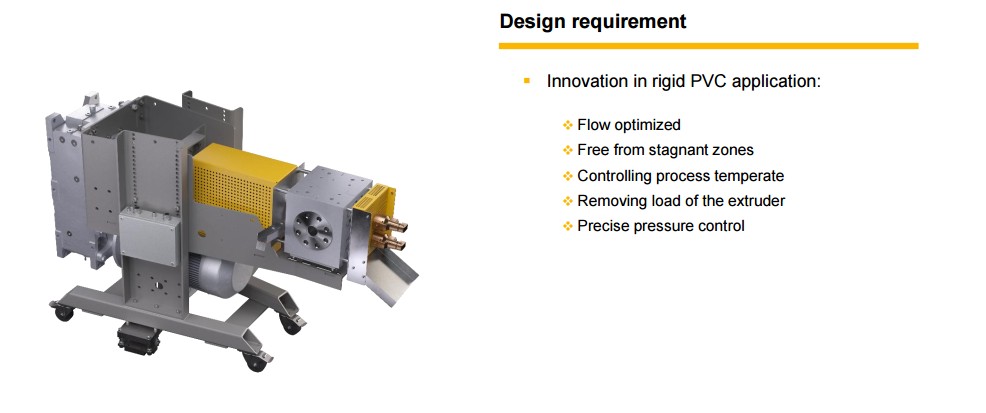

Maag’s new x6 melt pump for PVC extrusion changes that equation. It is designed specifically to handle the challenges of PVC, taking over the pressure-building job so the extruder can focus on plasticizing. That single shift opens the door to a much more stable, efficient process.

What it means for your line

- More output from the same equipment – Stable pressure lets you safely push throughput up by as much as 50%.

- Lower energy bills – By offloading the extruder, you can cut power consumption by up to 50%.

- Consistent quality – The pump smooths out flow, reducing pulsation by up to 90%. That means more consistent wall thickness, fewer rejects, and tighter process control.

- Cooler, safer processing – Lower melt temperatures mean less shear, fewer thermal stresses, and more reliable performance for PVC’s sensitive chemistry.

The ROI is real

Here’s a simple example. Take a PVC line running 2,200 lbs/hour for 8,000 hours a year.

Just a half-percent improvement in pressure stability, reducing overuse of resin, can save about EUR 120,000 in raw material in only six months. Factor in the reduced energy draw and the ability to increase throughput, and the pump often pays for itself in well under a year.

Why this pump is different

PVC isn’t just another polymer, and Maag didn’t treat it like one. The x6 pump features optimized flow paths with no stagnant zones (so the resin doesn’t sit and degrade), innovative shaft cooling to keep temperatures in check, and flexible configurations that can be retrofitted to existing lines. It’s an innovative solution to some of the toughest headaches in PVC extrusion.

Let’s talk about your line

If you’re looking for ways to improve your PVC pipe extrusion operation, the Maag x6 melt pump is worth a serious look.

📩 Contact me at Gauge Advisor and let’s:

📄 Discuss your process & explore efficiencies

🏭 Schedule an onsite visit at your plant

💬 Connect today to discuss your project

Founder, Gauge Advisor LLC

👉 Read these next:

Extrusion Melt Pumps: How MAAG Pumps Improve Output and Product Consistency

How to Weigh Resin Coming Off a Railcar (and Why It Matters for Your Bottom Line)