Laser micrometers are critical for precision measurements in industries like manufacturing, extrusion, and quality control. The choice between single, dual, and triple axis models depends on application requirements, measurement complexity, and tolerance demands. Here’s a quick guide to selecting the right micrometer for your needs.

Key Differences in Axes and Capabilities

| Axis Count | Measurement Principle | Key Measurements |

|---|---|---|

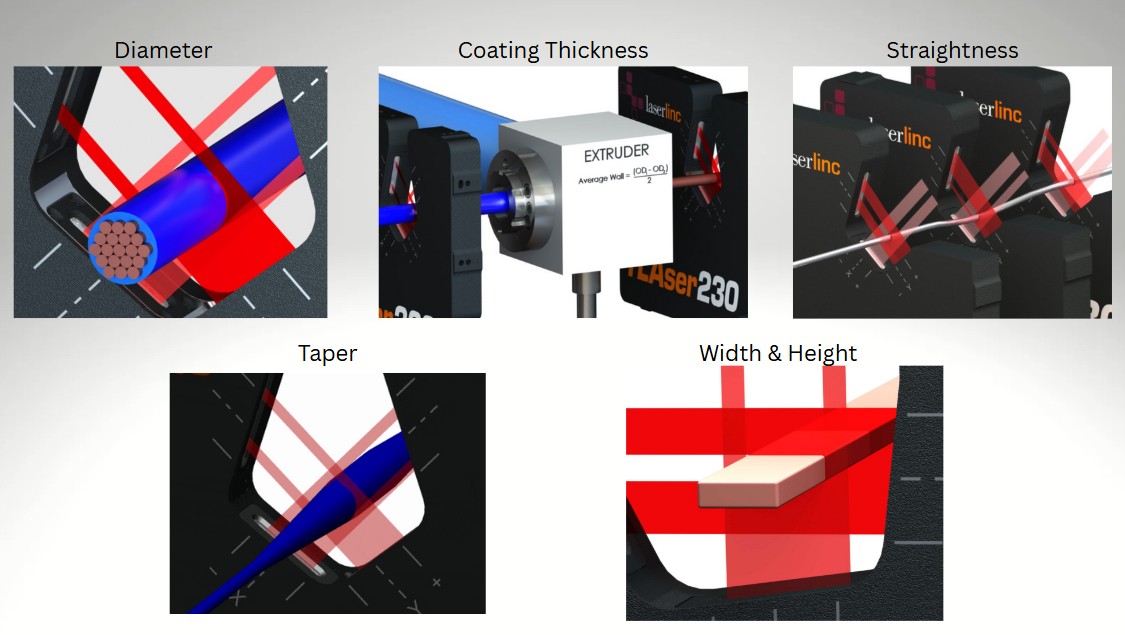

| Single Axis | One laser measures product from a single direction | Outside Diameter Flaw Detection Edge Position Gap (between objects) Part Height Part Length Part Width Part Position Part Deflection Taper Total Indicated Runout Shrinkage Multi-Strand Wall Thickness* Straightness* Ovality* |

| Dual Axis | Two lasers measure product from a two co-planar directions | Outside Diameter Ovality Eccentricity Flaw Detection Coating Thickness Part Position Straightness Taper Width & Height Shrinkage Multi-Strand |

| Triple Axis | Three lasers measure product from three 60°-separated planes | Outside Diameter Ovality Flaw Detection Coating Thickness Part Position Straightness Taper Shrinkage Multi-Strand |

Which Laser Micrometer Do I Need?

Now that we’ve broken down what each type of laser micrometer can measure, let’s get into the real-world side of things: when you would actually use each one.

When to Use a Single-Axis Laser Micrometer

Single-axis micrometers are great for measuring both round and non-round parts. They are a cost-effective solution, but have a trade off when it comes to flaw detection.

For round parts, a single-axis micrometer gives you a basic diameter check. It’s quick and simple. The downside? It has limited flaw detection. Since the laser only looks from one direction, it will miss defects on the unseen side of the part. Think of it like the sun shining on Earth: one side is illuminated, but the other side stays dark. Same idea here. If a diameter anomaly isn’t in the line of sight, it will not be caught.

That said, single-axis micrometers are excellent when it comes to non-round parts. Plus, they’re the optimal choice when you need to measure:

- Gaps between parts or Multi-Stranded products

- Length, Width, Height, and Position

- Total Indicated Runout (TIR)

- Part deflection

Common single-axis applications include:

- Multi-strand wire measurement

- Twisted or coiled products

- Drawn & stranded wire

- Profile extrusions

- Hot steel

Here’s a bonus: using a specially designed single-axis micrometer will enable you to measure outside diameter, inside diameter, and wall thickness of tubing. Consider the LaserLinc ID/OD/Wall system for this measurement.

When to Use a Dual-Axis Laser Micrometer

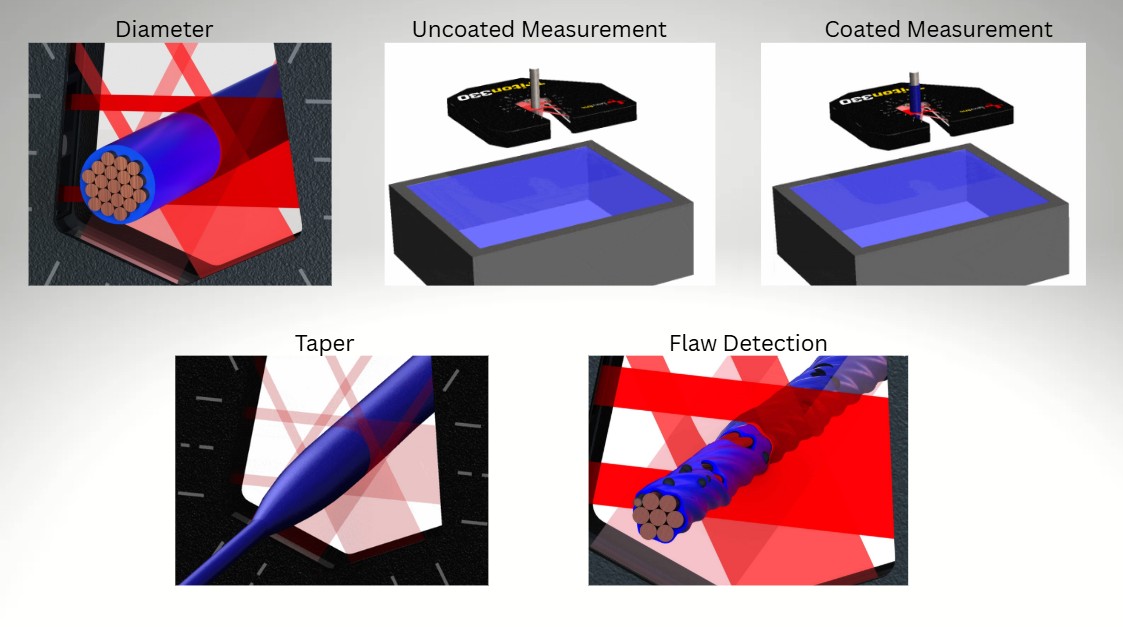

Dual-axis micrometers step things up when you need a better picture of what’s going on with a part. Especially round parts.

Instead of just one view, a dual-axis micrometer measures from two perpendicular directions (X and Y axes). This gives you a much better idea of true diameter and out-of-roundness. It will help you catch ovality, major diameter variations, or anything that’s a little out of spec but cannot be measured with a single-axis setup.

Use a dual-axis micrometer when:

- You need more accurate diameter measurements.

- You want to detect ovality, out-of-round conditions, position, or straightness.

- The part could shift or vibrate slightly during measurement

Common dual-axis applications include:

- Round extrusions and coatings: insulated wire, cable, hose, pipe, tube

- Corrugated products: flexible gas pipe, respiratory tubing, etc

- Multi-strand magnet wire, monofilament

- Profile height & width (simultaneously)

- Piece-part inspection

Dual-axis systems are popular in extrusion lines, wire production, and tubing applications where diameter consistency matters, but full profiling isn’t absolutely critical.

When to Use a Triple-Axis Laser Micrometer

If you need even higher accuracy on a part’s measurement, you’ll want a triple-axis micrometer.

Triple-axis systems measure from three different directions, building a much more complete profile of the part. They can measure outside diameter and ovality around nearly the entire circumference even better than a dual-axis unit can.

You’ll want a triple-axis micrometer when:

- You’re using measurements for automatic closed loop line control (high throughput extrusion and coating applications).

- The product rotates, vibrates, or isn’t perfectly stable.

- Maximum precision and flaw detection are critical.

- You want comprehensive profiling of the part.

- You need ovality

Common triple-axis applications include:

- Medical: tubing, catheters, balloons, cannulas, rods, etc

- Aerospace & Automotive: wire, hose, components, etc

- Other mission critical industries & components

- Piece-part inspection

Triple-axis setups are common in industries where even small shape changes can cause big problems downstream.

💡Quick Engineer’s Tip

When in doubt, step up a level.

If accuracy, flaw detection, or production line closed-loop control are critical in your process, consider going from a dual to a triple-axis system. It will cost a little more upfront, but it can save you huge costs later by catching bad parts before they turn into scrap, downtime, or warranty claims.

Final Thoughts

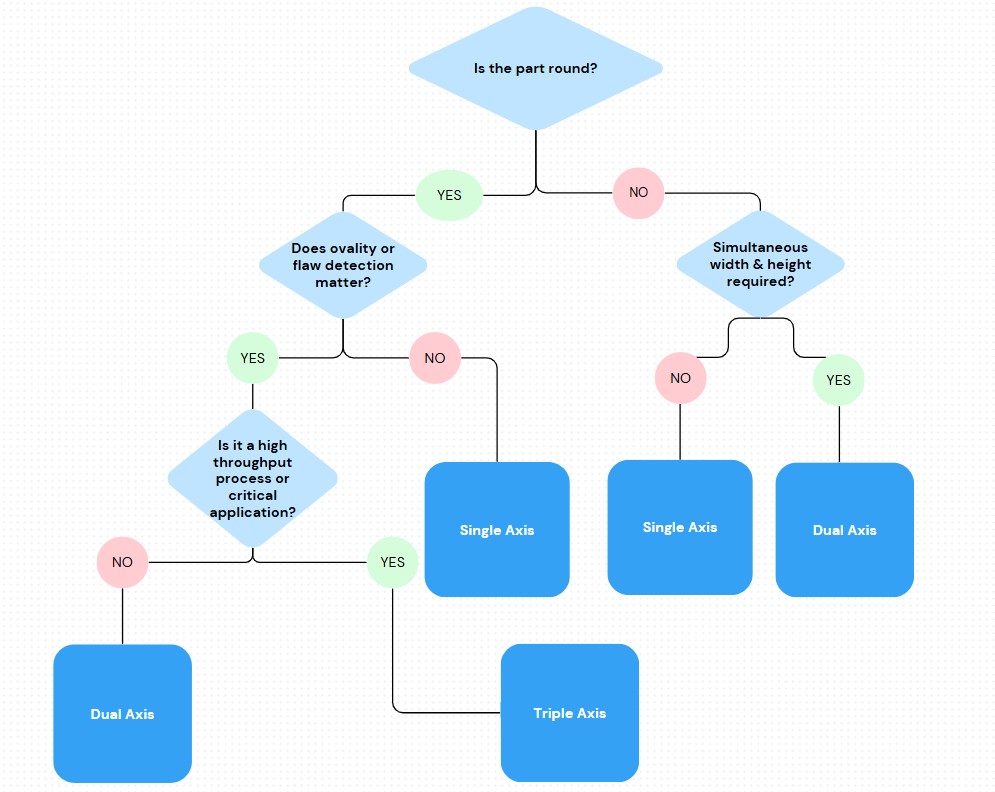

Choosing the right laser micrometer comes down to how much information you need and how stable your parts are during measurement.

- Single-axis: Basic, fast, and great for non-round parts.

- Dual-axis: Better coverage, great for round parts with tighter tolerances.

- Triple-axis: Excellent profiling & best precision.

Each application is unique, although this simplified decision tree will help guide your logic:

Want even more accuracy? For mission-critical products that require 100% surface inspection and flaw detection, mounting multiple triple-axis micrometers is an option. This enables the operator to catch even the smallest defects that affect product diameter. However, at this point an engineer should consider alternate technologies such as LaserLinc’s FlawSense. This unit uses laser triangulation & cameras to create a high-speed 3D surface map of the tube as it moves through the measurement head. This allows for 360-degree detection of physical defects, including slits, cracks, carbons, intrusions, protrusions, and other anomalies along the tube’s length. While a laser micrometer can only catch defects affecting diameter, FlawSense can capture much more.

Looking for a Supplier?

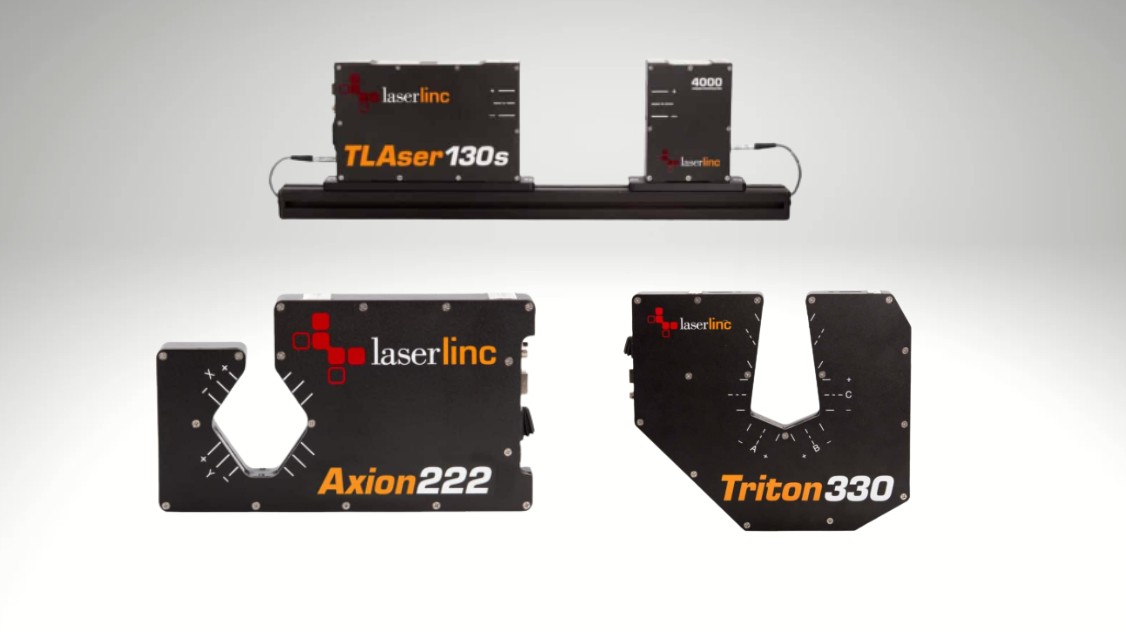

If you’re considering upgrading or adding laser micrometers to your line, LaserLinc is a name worth knowing. LaserLinc specializes in high-precision laser micrometers for a wide range of industries — including extrusion, medical tubing, wire and cable, automotive, aerospace, and composite materials.

With a full range of single, dual, and triple-axis systems, & custom solutions, LaserLinc will supply the right equipment for your application. Plus, with immediate technical support, available by phone and remote connection, you’ll have the help you need, exactly when you need it. Moreover, each LaserLinc system comes with unique software that is operator friendly and provides valuable SPC data.

What You Get with LaserLinc:

📅 4-Year Industry-Leading Warranty

🔧 2 Years of Unlimited Technical Support

✅ U.S. Based Design, Service & Manufacturing

Take the Next Step

📄 Request detailed technical specs

📬 Send samples for evaluation & testing

💬 Connect today to discuss your application

Founder, Gauge Advisor LLC

👉 Read these next:

Catheter, Cannula, and Guidewire Measurement: Choosing the Right Laser Micrometer Setup

Wire and Cable Measurement Solutions for Diameter, Coating, and Defect Detection