In plastics extrusion, controlling melt pressure and flow consistency is critical to achieving tight tolerances, high Cpks, and minimizing scrap. For process engineers tasked with optimizing line performance, a melt pump (also referred to as a gear pump) is a core component that improves stability, throughput, and product quality.

MAAG’s x6 series melt pumps are engineered to address these challenges head-on by delivering precise pressure control, minimizing pulsations, and reducing thermal variation. If you’re looking to increase line efficiency while improving repeatability across runs, it may be time to reevaluate what a melt pump can do for your process.

💡 Why Use a Melt Pump on Your Extruder?

Adding a melt pump between your extruder and die isn’t just an upgrade. It’s a strategy for better control and efficiency. Here’s what it brings to your process:

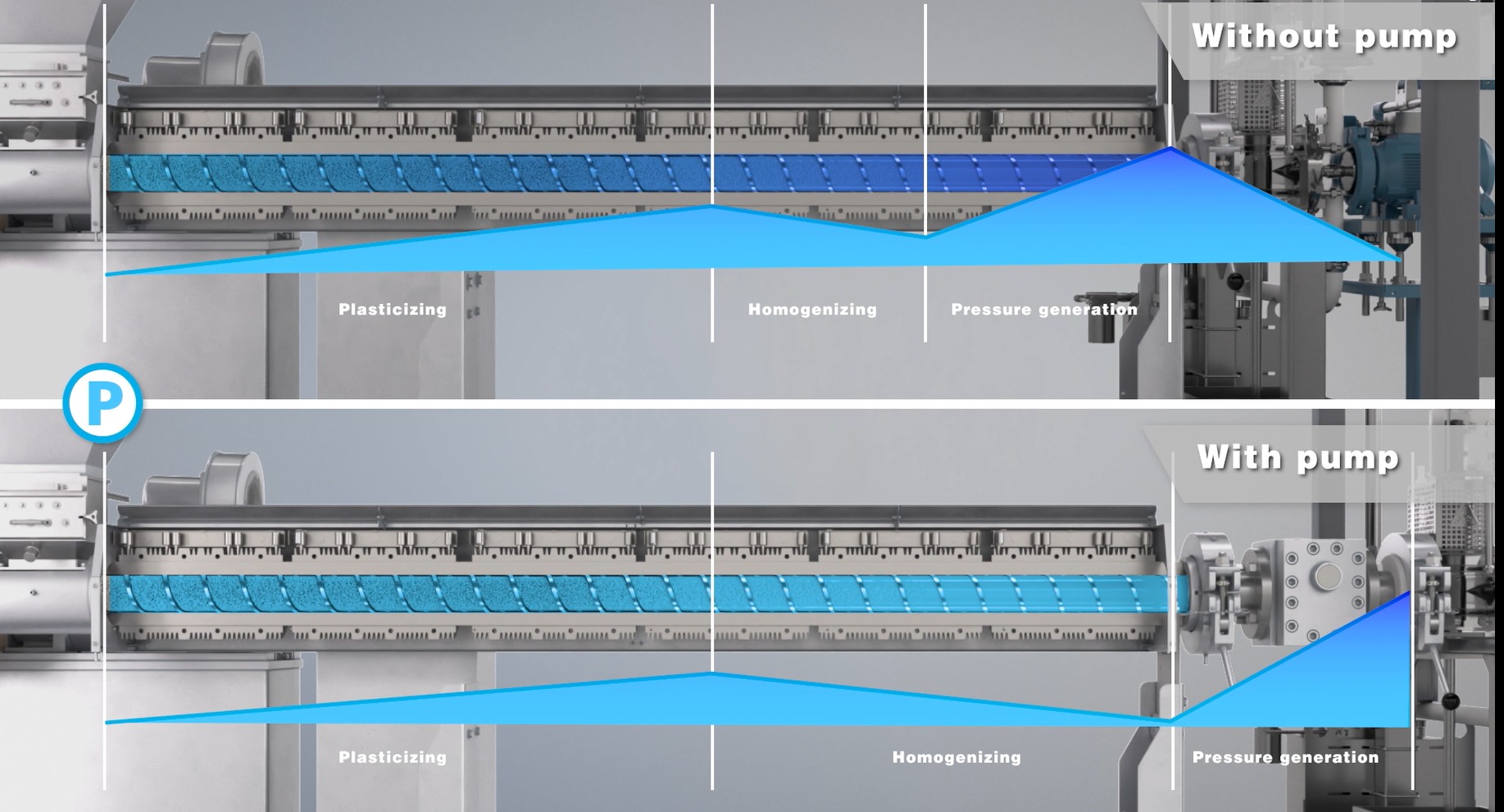

- Consistent Pressure at the Die: An extrusion melt pump handles pressure generation downstream, allowing the extruder to focus on melting and mixing. This separation leads to smoother flow and a more stable process.

- Reduced Melt Temperature: By offloading pressure from the extruder, the melt sees less mechanical energy input. This results in lower melt temperatures and improved product quality.

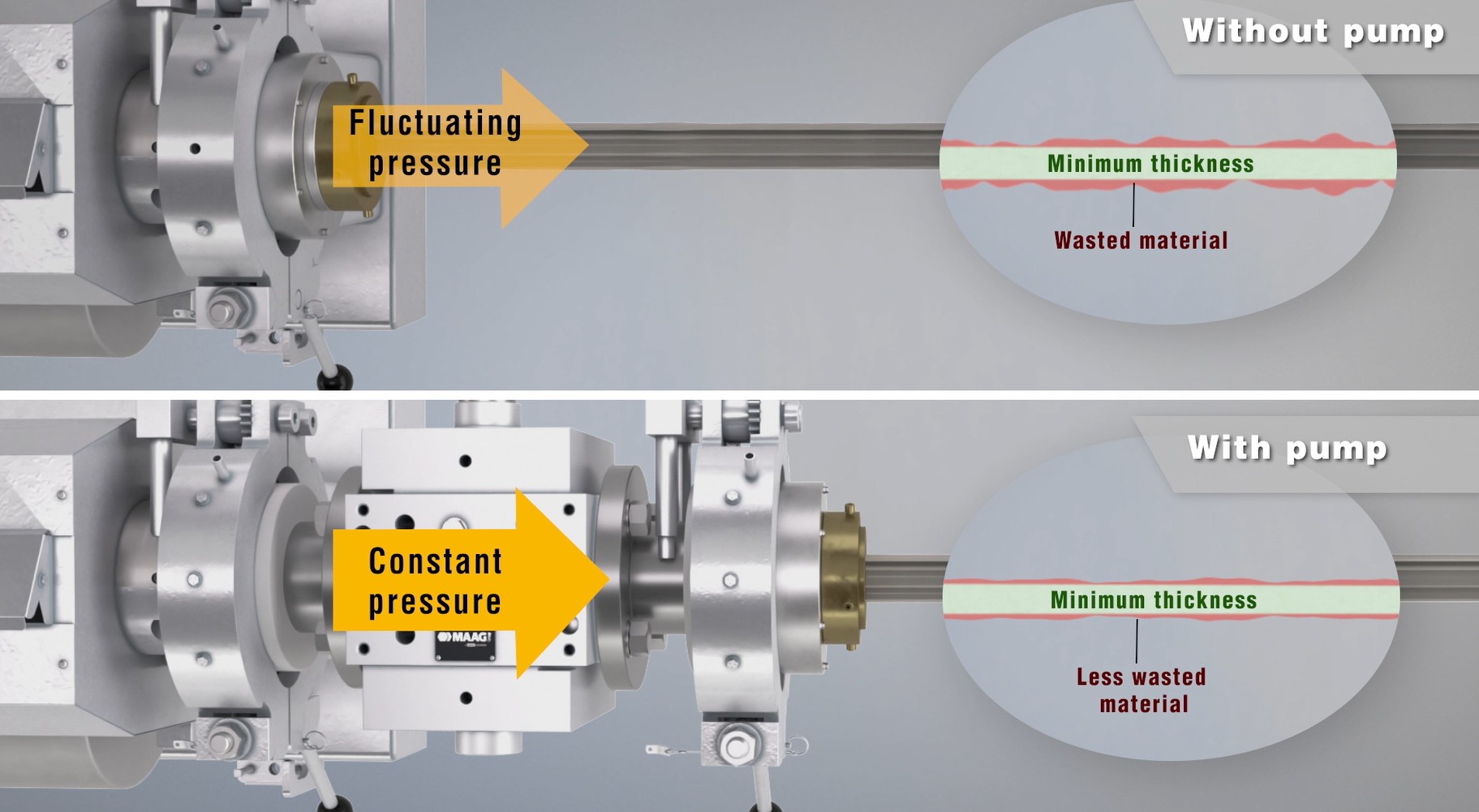

- Improved Product Uniformity: Melt pumps drastically cut pressure fluctuations. Without one, melt fluctuation can range from 3–7%. With a traditional pump, that drops to 1–2%. MAAG’s x6 pump? Just 0.5% melt fluctuation. This means tighter tolerances and higher Cpks.

- Increased Extruder Life: With less back pressure and torque demand, your extruder screws and barrel experience less wear.

- Higher Throughputs: Melt pumps enable increased throughput at lower motor loads by allowing the extruder to operate more efficiently.

What Sets the MAAG x6 Melt Pump Apart?

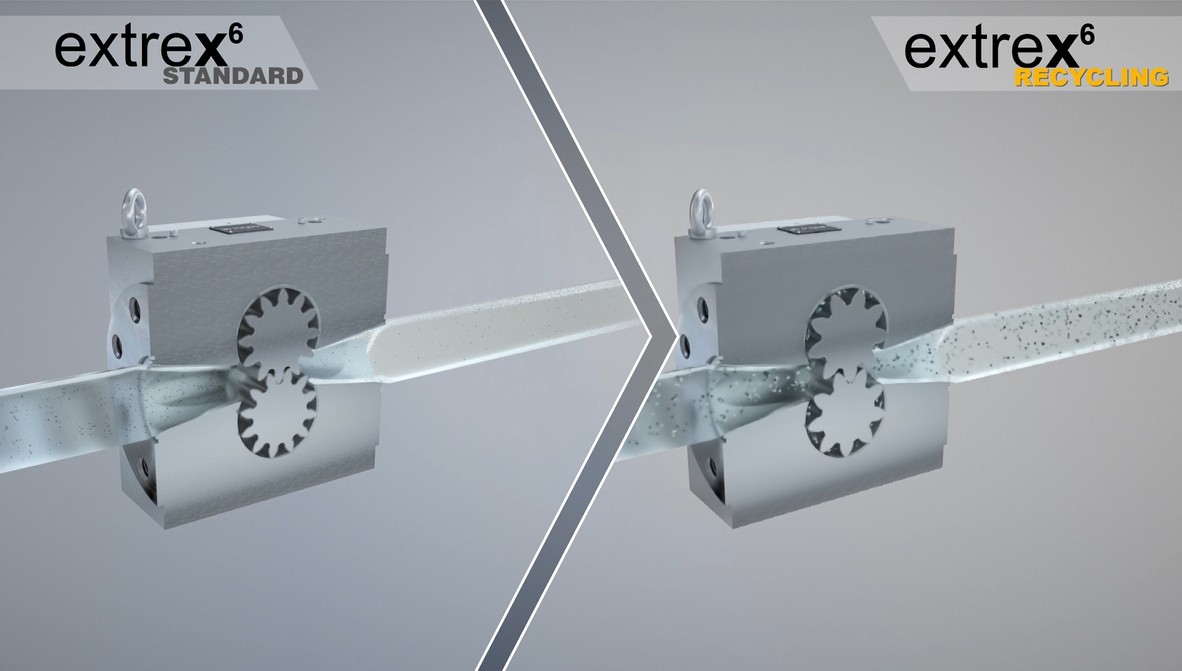

MAAG’s x6 series is built for demanding applications: high filler content, recycled material, or demanding profiles. Some standout features include:

✅ Superior Process Stability

- Up to 90% pulsation reduction compared to legacy systems.

- Reduced variability leads to higher Cpks, which is especially important in regulated or tight-spec applications like medical tubing or multilayer film.

🔧 Robust Construction for Demanding Materials

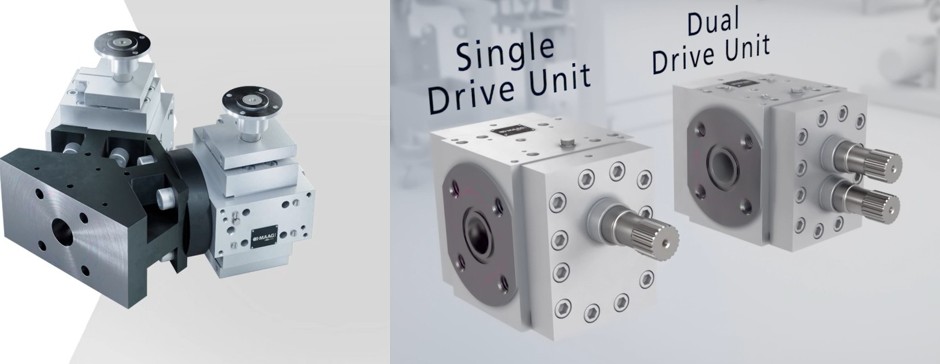

- Narrow gear spacing eliminates shaft deflection even at high pressures.

- Optional dual drive unit is ideal for abrasive materials or high-regrind content, spacing the gear teeth to prevent damage from coarse particles.

- Bearings engineered for dry running in recycled applications & specialized channels for lubrication unique to each application.

🌡️ Smart Thermal Management

- Cooling blocks prevent leaks and thermal degradation in high-viscosity or PET applications.

- Rotary Unions added to aid in cooling of elastomers such as rubber.

- Three discrete heat zones (inlet, pump, outlet) provide more precise thermal control.

🧠 Integrated Control & Safety

- MAAG’s maax 3S control system simplifies startup, shutdown, and operation. This makes it perfect for retrofits.

- Alarms for low inlet pressure, high outlet pressure, and other events help protect your line from damage.

🔄 Long-Term ROI

- x6 class pumps last up to 50% longer than traditional melt pumps.

- Reduced scrap: up to 10% less material rejected thanks to improved consistency.

- 12% lower energy consumption through optimized thermal and mechanical design.

- Shaft surfaces are 25% more wear-resistant, reducing maintenance frequency.

Tailored for Your Application

With pressure ratings from 370 to 700 bar and throughput from 40 to 15,000+ kg/h, MAAG has a solution whether you’re extruding film, sheet, tubing, profiles, or reprocessing recycled material. Their x6 product family includes:

- GU (General Use)

- EP (Extra Pressure)

- SP (Super Pressure)

- MP (Maximum Pressure)

And with accessories like support carts, control systems, and screen changers, the system is engineered to fit seamlessly into your line.

Is It Time to Add a Melt Pump?

If you’re seeing melt fluctuations, high scrap rates, or variability in gauge, a melt pump may be the missing link. If you’re already using one, upgrading to a MAAG x6 pump offers a measurable jump in performance and efficiency.

📞 Take the Next Step

Interested in learning more? Contact Gauge Advisor for guidance on specifying the right melt pump for your extrusion line.

📄 Discuss your process & explore efficiencies

🏭 Schedule an onsite visit at your plant

💬 Connect today to discuss your project

Founder, Gauge Advisor LLC

👉 Read these next:

A Smarter Way to Run PVC Pipe Extrusion: Maag’s New x6 Melt Pump

Blenders and Thickness Gauges: The Real Profit Drivers in Film Extrusion and Which Ones to Use

How to Weigh Resin Coming Off a Railcar (and Why It Matters for Your Bottom Line)